It is possible to make bunker fuel oil that meets all ISO 8217 specs for residual fuels, complying with the International Maritime Organization's (IMO) forthcoming 2020 regulations without using gas oils, enabling ship owners to avoid thermal shocks and other fuel- switching headaches. Further, enough low-sulfur components exist in the US Gulf Coast (USGC) market to comfortably produce 0.5 wt % sulfur IFO380 without requiring refiners to reconfigure their plants or add expensive residue desulfurizers or hydrocrackers.

Assuming a global IFO380 consumption of about 300 million tonnes/year, neither budgets nor markets would be stressed to secure the lower-sulfur crudes or blendstocks required to produce these bunkers.

The IMO's upcoming 0.5 wt % specification for bunker fuel oil scheduled to take effect Jan. 1, 2020, has sparked a mild hysteria among the refining industry as to what course to take for compliance with the new regulation.

Some refiners are wishing it away, while others are ignor ing it for the moment in hopes of some miracle that will de lay or eliminate the compliance deadline entirely.

We examined six options currently outlined for 2020 compliance: switching to marine gas oil (MGO), using IMO Emission Control Area (ECA)-compliant fuels, producing 0.5 sulfur wt % fuels, using scrubbers, switching to LNG, or doing nothing.

This article discusses Refinery Automation Institute LLC's (RAI) research on the feasibility of making bunker fuels with today's widely available blend components as compared with research conducted by IMO CE Delft and IMO-unsolicited Ensys Energy & Systems Inc.-Navigistics Consulting. Results indicate 2020-compliant bunker fuels can economically be produced using existing blend components.

RAI study

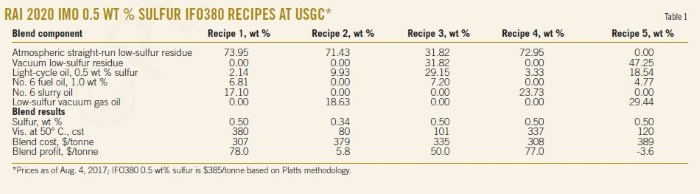

Released in August 2017, RAI's 2020-compliant bunker study examined in detail USGC availability of suitable blend components to make 2020-compliant bunker fuels.3 We used these components and bunker-blend optimizer software to verify 2020-spec compliance and cost-effectiveness.

The criteria used in selecting widely available blend components centered on low–sulfur crudes to avoid the need for more costly desulfurization via additional residue hydro- cracking and hydroprocessing when using high-sulfur crude feedstock.

The blend components used for recipe testing included:

– Straight-run residue, < 1.0 wt % sulfur.

– Vacuum residue, < 1.0 wt % sulfur.

– No. 6 residual fuel oil, 0.3-1.0 wt % sulfur.

– Hydrotreated light-cycle oil.

– Slurry oil.

– Vacuum gas oil, < 0.5 wt % sulfur.

– Russian black gas oil.

– Marine gas oil.

Pricing of these blend components—which are all currently available in the USGC—was based on third-party in- dependent price assessments from Platts, OPIS, and Argus. We estimated pricing for some components based on the Platts methodology of extrapolating between a pair of reference fuels that bracket the desired unknown component properties.

For residues, we explored a number of widely available low-sulfur crudes—including Cabinda, Minas, Girassol, Bonny Light, and some crude blends such as Saharan, BTC, and Palanca—to produce residues with a sulfur content in a range of 0.3-0.6 wt %.6

IMO CE Delft study

A review of the IMO CE Delft study indicates a proposed compliance solution of gas oil with a viscosity of 14-17 cst at 50° C. using a recipe consisting of about 75% gas oils and 25% hydrotreated (desulfurized) atmospheric residue or H- Oil bottoms. The resulting product, however, could not be classified as bunker, in terms of either properties or price. The proposed recipe also calls for components that currently don't exist in certain geographic areas (e.g., the unavailability of visbreaker bottoms in the US and extreme rarity of H- Oil unit bottoms globally).

For Asia, IMO proposes a bunker fuel recipe with viscosity of 110 cst at 50° C., again using components that are hardly available because the process units either don't exist or are in limited use, such as those that produce hydrotreated atmospheric residue and H-Oil bottoms.

Tables 2 shows 0.5 wt % sulfur bunker recipes for Europe, the US, and Asia-Pacific as presented in the IMO CE Delft study.

IMO-unsolicited Ensys-Navigistics study

In October 2016, Ensys Energy and Navigistics Consulting released a joint parallel-availability study that concluded enough blend components won't exist to meet 2020 specs, nearly an opposite conclusion to that suggested by the IMO CE Delft study, despite more or less the same recipes using large volumes of treated residue (<1 wt % sulfur).

Source: Ara Barsamian, Lee E. Curcio, Refinery Automation Institute LLC, Morristown, NJ